THELONDONERHOTEL.

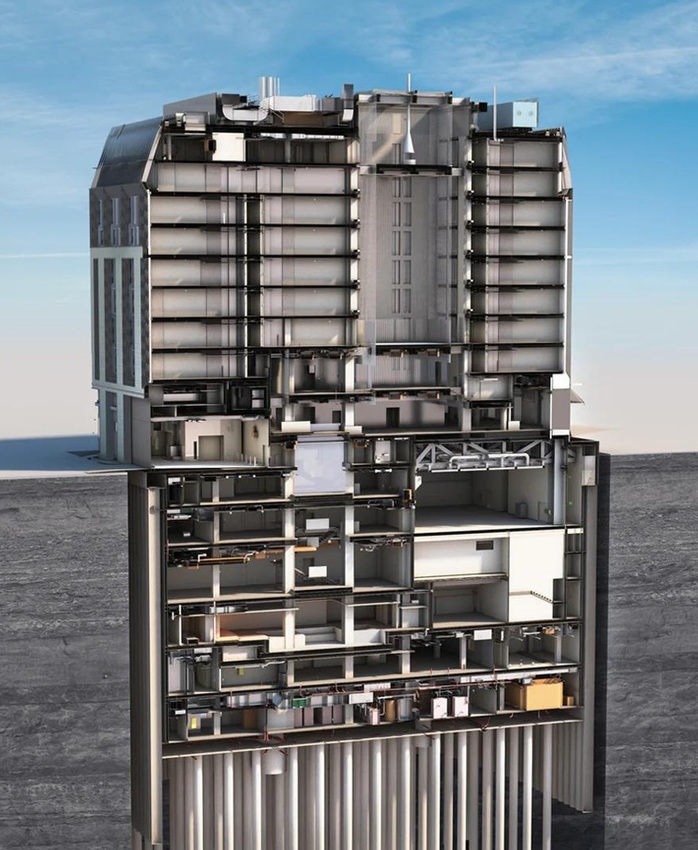

THE WORLD'S FIRST SUPER BOUTIQUE HOTEL WITH THE DEEPEST HABITABLE BASEMENT IN EUROPE.

CLIENT: EDWARDIAN HOTELS

STATUS: COMPLETE

LOCATION: LEICESTER SQUARE

Located in the heart of Leicester Square with a footfall of over 35 million, we delivered an integrated solution for Edwardian Hotels latest development.

This project involved the development of a bespoke engineering solution to deliver the deepest habitable basement in Europe. It required the excavation of 80,000m³ of material and over 8,000 lorry movements. Located in a logistically challenging area of central London, the project demanded extensive coordination with stakeholders.

All work was delivered using our in-house expertise, engineers, plant operators, and owned equipment, including bespoke plants such as the only telescopic grab in Europe capable of excavating to that depth.

Providing a comprehensive, integrated solution ensured the client received programme certainty throughout the project.

Subterranean Development

We excavated the deepest commercial basement in London at the time, bringing with it challenges such as ground movement risks, groundwater ingress, and limited working space. Despite these complexities, our meticulous planning and advanced construction techniques mitigated risks and ensured the project’s success.

Logistical Operations

With the site bounded by roads and measuring less than 50m by 50m, efficient earth removal was essential. We executed a thoroughly coordinated operation, using our own fleet of safety-enhanced tippers and advanced vehicle management technology to remove 75,000m3 of London clay, the equivalent of 26 Olympic swimming pools.

Third-Party Assets Management

The project was in close quarters with critical Thames Water pipes and a UK Power Network electricity supply, requiring careful coordination and monitoring. Our commitment to safety and regulatory compliance allowed the successful installation of the basement wall despite its proximity to the UKPN network asset.

Installation of Steel Trusses

Transporting and installing six massive steel trusses, each weighing 55 tons and as long as two double-decker buses, posed a significant logistical challenge. Despite the complexities of maneuvering within a bustling city, meticulous planning and the use of a 750-tonne mobile crane facilitated the precise placement of the trusses, ensuring structural integrity.

STRUCTURAL ENGINEER: ARUP

PROJECT MANAGERS: BLUE SKY BUILDING

Despite operating within a constrained site and facing numerous logistical hurdles, innovative solutions and meticulous planning ensured the project’s success.